Flow Formed Tubes

Flow Formed Tubes

Radar Cooling Assemblies

Titanium Manufacturing

Special Metal Manufacturing

Heavy Structures

Special Purpose Machines

About Flow Forming

An advanced, cold forming process used to manufacture dimensionally precise, round, seamless, hollow components. We offer the largest manufacturing facilities of Flow Formed Tubes With state-of-art In-House Flow forming machines. We can undertake complex tube shapes and manufacture precision flow formed tubes of high-pressure ballistic applications. We manufacture tubes using all metals. Our satisfied customers come from some of the most demanding military, nuclear, aerospace and industrial markets. They appreciate the fact that the flow-forming process can be a cost-effective alternative to conventional manufacturing practices.

An advanced, cold forming process used to manufacture dimensionally precise, round, seamless, hollow components. We offer the largest manufacturing facilities of Flow Formed Tubes With state-of-art In-House Flow forming machines. We can undertake complex tube shapes and manufacture precision flow formed tubes of high-pressure ballistic applications. We manufacture tubes using all metals. Our satisfied customers come from some of the most demanding military, nuclear, aerospace and industrial markets. They appreciate the fact that the flow-forming process can be a cost-effective alternative to conventional manufacturing practices.

Methods

Forward Flow Forming

Forward Flow forming is used for components with one closed or partially-closed ends such as a closed bottom or partially closed cylinder. Once the preform is inserted over the mandrel, its inner bottom is locked against the tip of the mandrel using hydraulic force from the tail stock. As the mandrel and preform rotate, the carriage is made to travel in a right to left direction. The rollers apply force to the outside diameter of the preform and there is a pre calculated amount of wall reduction. As the wall is thinned and the outer diameter is reduced in size by the combination of controlled radial and axial forces, the finished component takes shape to the right of the rollers. The balance of a flow formed material moves ahead and to the left of the rollers.

Reverse Flow Forming

Reverse Flow forming is utilised to produce a component with two open (unrestricted) ends such as a tube. Once the preform is placed on the mandrel, it is pushed to the left side against the drive ring at the end of the mandrel. Like Forward Flow forming, the carriage also moves in a right to left direction. As the axial thrust of the rollers applies force to the right of the preform, the metal is pushed into and entrapped by a series of serrations on the face of the drive ring. This assures the necessary rotational drive of the preform during the process cycle. With the carriage travelling left, the flow formed metal moves to the right, under and in the opposite direction of the rollers.

Shear Flow Forming

Shear forming is used to form conical, radial, parabolic or ogival geometries. The preforms are typically in the shape of circular discs. With the preform held firmly against the nose of the mandrel by hydraulic force from the tail stock or by other mechanical means, the carriage is made to move right to left. The rollers plastically deform (“shear”) and flow the available metal against the mandrel. Shear forming can be described as a combination of metal spinning and forward flow forming.

Benefits

Dimensional Benefits

Precision Flow forming is capable of dimensional accuracies well beyond other forming methods. Since flow forming tooling is subject to little or no wear, the CNC controlled process offers consistent and repeatable accuracies part to part, lot to lot.

Precision: The all-around dimensional controls for diameters and walls offered by precision flow forming will reduce or eliminate your need for secondary turning, grinding and honing operations. The high degree of roundness, straightness and concentricity achievable by our flow forming process will often reduce or eliminate the necessity for straightening and balancing your finished component. The very fine surface finishes generated by flow forming on the inner and outer diameters will, in most cases, also void your requirement for honing and/or polishing.

Thin walls: Precision flow forming can generate economically and without difficulty your very thin and precise wall thicknesses regardless of the diameter size of the component. If you have had to contend with the difficulties and costs of managing the deflection of a thin metal body under turning or grinding operations, you will come to greatly appreciate our precision flow forming process.

Varied Walls: Unlike any other type of forming process (i.e. extruding, forging, impact extruding, deep drawing, pilgering, drawn over mandrel, etc.), flow forming can vary the wall thickness of a component at any place and as many times as desired along the length of the flow formed component without additional cost.

Hardened Metals: Flow forming offers you the unique possibility of forming to size a pre-hardened work piece, thus eliminating the difficulties and high costs associated with final machining, grinding and honing of a hardened and distorted hollow component. Our precision flow forming method of manufacturing, allows us to achieve high dimensional accuracies and at the same time guarantee conformance to your required mechanical properties right off the flow forming machine.

Metallurgical Benefits

Grain Structure: As a result of the cold work (strain hardening) that occurs during the process cycle, a flow formed component will have considerably higher mechanical properties than the ones of the starting material. Typically, the preform material is plastically deformed with wall reductions in excess of 75% of the starting wall thickness, causing a substantial refinement of the grain structure and a total realignment of the grains’ microstructure in a very uniform, axial direction. The greater the wall reduction, the finer the grain’s microstructure of the finished component. If necessary, the grain structure can be recrystallized by a post-forming annealing cycle

Crystallographic Texture: During the flow forming cycle, all the crystals that form the starting grain structure will be displaced and realigned. The overall orientation of these crystals is known as ” texture”. Nearly all mechanical properties are influenced by the metal’s texture. In a flow formed component, the overall texture is always uniformly oriented. For example, in the case of Hexagonal Closed Packed (HCP) materials such as Titanium and Zirconium, their flow formed crystals will have radially oriented basal planes. This condition increases the biaxial strength of the metal, effectively increasing the circumferential strength. The flow formed crystallographic texture can be further intensified by a post flow forming annealing cycle. On a micro level, the annealing will recrystallize the grain structure while on an atomic level; the texturing effect will be magnified.

Mechanical Benefits

Metal Properties: Flow forming is a cold working process which, through its strain hardening of the base metal substantially increases Yield and Tensile Strengths of the formed material. Certain customers choose to take advantage of the improvement in mechanical properties by effectively designing thinner walls for lighter components. Others prefer post-forming stress-relieving or solution annealing of the flow formed component to remove residual stresses. In other cases, the flow formed component will be heat-treated or aged to alter the levels of achieved strength, hardness and ductility into specification requirements.

Seamless: One major benefit offered by flow forming is its seamless construction. Quite often, we are also able to integrate more than one previously separate component into the same seamless flow formed structure

Savings: A seamless component will eliminate manufacturing problems associated with welding, such as heat-affected zones, part distortion, weld porosity and failures, as well as the inherent costs of the weld, its radiography and general testing. Elimination of all the above should be factored in the cost savings when comparing the utilization of a seamless flow formed component.

Economical Benefits

Precision Flow forming is a chipless, cold forming process, capable of forming high strength and hard-to-form metals to the desired geometry with tight dimensional controls throughout. With the ever-increasing costs of metal, many customers have come to greatly appreciate our ability to flow form to net shape.

No Waste: We start with a short, thick preform and typically flow form it four to six times its starting length. Material waste and labour cost are minimal. If your program is burdened by the costs and waste associated with gun drilling/trepanning of solids and/or the machining of extrusions, you are a good candidate for flow forming.

Net Shape: In almost all cases, we can flow form to net shape, maximizing material utilization while eliminating post-forming machining.

Seamless: Our process is seamless. At times we can also integrate more than one of your components in the same flow formed component. Cost of welding, related problems and necessary testing are all eliminated

Hardened Metals: With flow forming, we can form your component from pre-hardened metal to your specified mechanical properties. If this approach is feasible for your part, you will eliminate the high costs of finish-machining and/or grinding a most likely heat-distorted component to its final accuracy.

Flanges: we can eliminate your costs of manufacturing, circumferential welding and related testing of end flanges or stub ends by integrating them as part of the seamless flow formed component

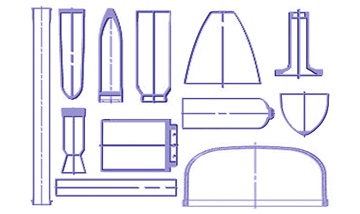

Geometries

Technical Consulting

- Design and development of workpieces based on forming technologies.

- Maintenance, repair and complete reconditioning of all types of spinning and flow forming Machines.

- Trading of used spinning and flow forming machines.

- Design, manufacturing and installation of forming machines.

- General Contracting.

- Technical Consulting and Engineering.